Technical IDC Cleaning

- Deep Technical Data Center Cleaning

- Post Construction Deep Cleaning

- Rack Technical Cleaning

- Tacky / Sticky Mats

Deep Technical Data Center Cleaning

Profile Solution Deep Technical Clean is an intensive service designed to achieve an ISO 14644-1 level 6 standard of air cleanliness. It addresses every area within the Data Centre, from the subfloor surface up to the underside of the panels and the floor surface, all walls, doors, ledges, and cabinet externals.

Profile Solution Deep Technical Clean is an intensive service designed to achieve an ISO 14644-1 level 6 standard of air cleanliness. It addresses every area within the Data Centre, from the subfloor surface up to the underside of the panels and the floor surface, all walls, doors, ledges, and cabinet externals.

- Technical Cleaning of IDC Up to Level 6

- Using Hepa Filters for proper Dust removal from IDC Room.

- Clearing Particles / Dust up to .03 Micron Level.

- Deep Technical Data Center cleaning Increase’s longevity and performance of hardware.

- Increased reliability of data center uptime.

Makes Your Data - Center environment Dust and Particle Free.

Post-Construction Deep Cleaning

Turning a building site into a controlled IT environment requires a inclusive and professional post-construction clean. Elimination of dust from walls, concrete dust from cut tiles, residue remaining on tiles and other coarse construction debris is essential for properly preparing a new room for equipment installation.

Turning a building site into a controlled IT environment requires a inclusive and professional post-construction clean. Elimination of dust from walls, concrete dust from cut tiles, residue remaining on tiles and other coarse construction debris is essential for properly preparing a new room for equipment installation.

- Post Construction Deep Clean Focus on all areas from the sub-floor to high levels.

- Removal of all ‘non-heavy’ construction debris.

Dry clean to visual acceptability.

- To fulfill your documentation requirements, Profile Solution post-construction cleans can be validated upon request with particle count to assist in eventual achievement of ISO 14644 controlled environment particle level standards.

- All Profile Solution cleaners arrive outfitted with the correct Personal Protective Equipment (PPE).

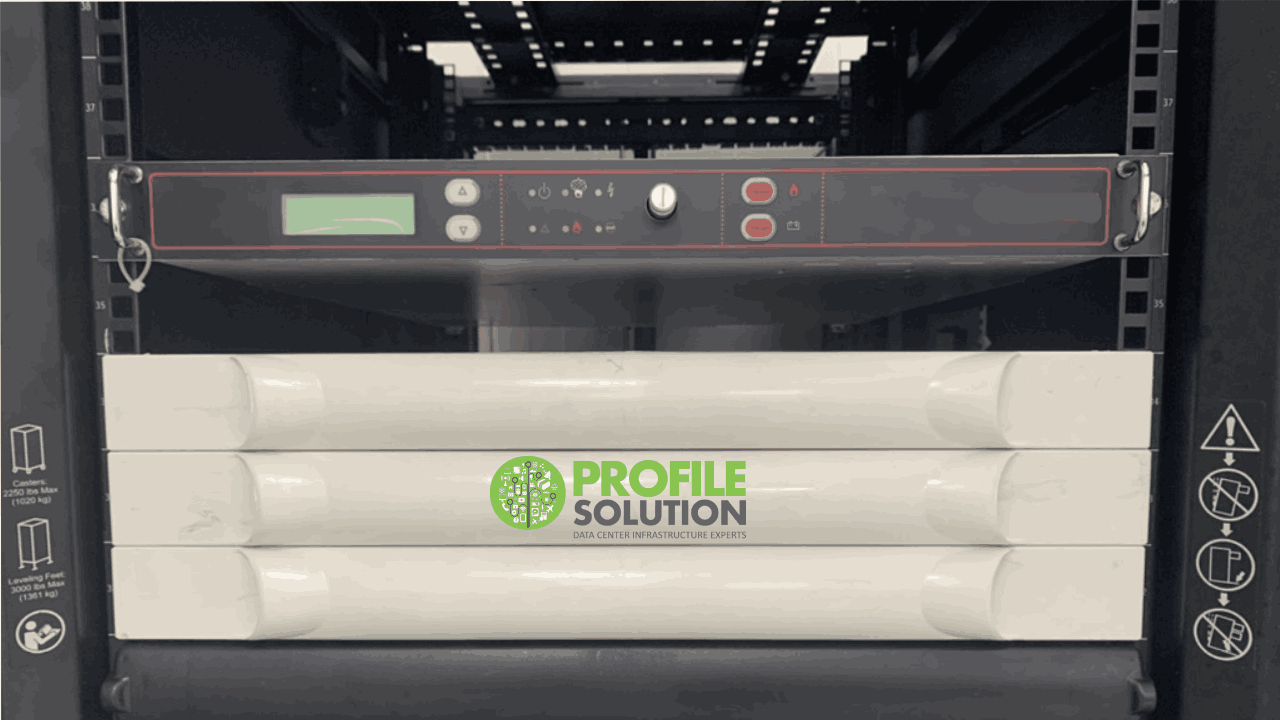

Rack Technical Cleaning

Server rack interiors and exteriors are especially susceptible to accumulation of airborne particles on horizontal surfaces. However, these areas are often not considered when establishing cleaning protocols for the rest of the data center. Based on experience, Profile Solution recommends that server racks undergo internal and external cleaning at least once a year.

Server rack interiors and exteriors are especially susceptible to accumulation of airborne particles on horizontal surfaces. However, these areas are often not considered when establishing cleaning protocols for the rest of the data center. Based on experience, Profile Solution recommends that server racks undergo internal and external cleaning at least once a year.

- Annual cleaning of these areas aids in maintaining ISO 14644 particle level standards for the entire room.

- Only electrical equipment dedicated to cleaning IT environments is used, with in-line safeguards to protect against power surges.

- Server rack cleaning targets vertical as well as horizontal surfaces, rack doors and removal of any gross contaminants such as cable cuttings and ties, screws, bolts and packaging materials.

- No moisture of any form is used; Profile Solution techniques employ low-lint disposable cloths which trap and remove loose dust without building up a static charge during use.

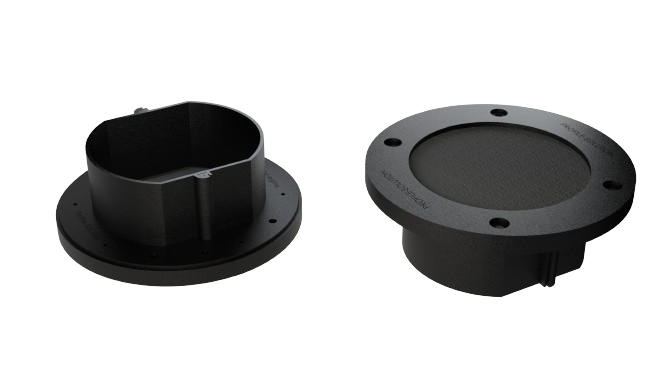

Tacky / Sticky Mats

Sticky mats are adhesive-coated contamination control mats that capture particulates from foot traffic and equipment wheels, preventing debris from hitchhiking into a clean room or controlled environment. The adhesive is non-transferable and contains a non-leching, nontoxic antimicrobial agent that provides long-lasting protection against the growth of mold, mildew, fungi, and algae.

Sticky Mats are adhesive-coated contamination control mats capture particulates from foot traffic and equipment wheels, preventing debris from hitchhiking into the clean room or controlled environment. Adhesive is non-transferable and contains a non-leeching, nontoxic antimicrobial agent that provides long-lasting protection against growth of mold, mildew, fungi, and algae.

- Dimension – 24″ x 36″

- 30 layers / Mat with numbered corner taps for easy monitoring of usage.

- Adhesive is strong, water soluble, anti-microbial and does not contain benzoic acid.

- Removes air-borne contaminants up to 95% of particles at the 0.3 micron range.

- Capture dirt and dust from foot traffic and equipment before they enter a controlled environment with these cleanroom mats

Deep Technical Data Center Cleaning

Profile Solution Deep Technical Clean is an intensive service designed to achieve an ISO 14644-1 level 6 standard of air cleanliness. It addresses every area within the Data Centre, from the subfloor surface up to the underside of the panels and the floor surface, all walls, doors, ledges, and cabinet externals.

- Technical Cleaning of IDC Up to Level 6

- Using Hepa Filters for proper Dust removal from IDC Room.

- Clearing Particles / Dust up to .03 Micron Level.

- Deep Technical Data Center cleaning Increase’s longevity and performance of hardware.

- Increased reliability of data center uptime.

Makes Your Data - Center environment Dust and Particle Free.

Post Construction Deep Cleaning

Turning a building site into a controlled IT environment requires a comprehensive and professional post-construction clean. Elimination of dust from walls, concrete dust from cut tiles, residue remaining on tiles and other coarse construction debris is essential for properly preparing a new room for equipment installation.

- Post Construction Deep Clean Focus on all areas from the sub-floor to high levels.

- Removal of all ‘non-heavy’ construction debris.

Dry clean to visual acceptability.

- To fulfill your documentation requirements, Profile Solution post-construction cleans can be validated upon request with particle count to assist in eventual achievement of ISO 14644 controlled environment particle level standards.

- All Profile Solution cleaners arrive outfitted with the correct Personal Protective Equipment (PPE).

Rack Technical Cleaning

Server rack interiors and exteriors are especially susceptible to accumulation of airborne particles on horizontal surfaces. However, these areas are often not considered when establishing cleaning protocols for the rest of the data center. Based on experience, Profile Solution recommends that server racks undergo internal and external cleaning at least once a year.

- Annual cleaning of these areas aids in maintaining ISO 14644 particle level standards for the entire room.

- Only electrical equipment dedicated to cleaning IT environments is used, with in-line safeguards to protect against power surges.

- Server rack cleaning targets vertical as well as horizontal surfaces, rack doors and removal of any gross contaminants such as cable cuttings and ties, screws, bolts and packaging materials.

- No moisture of any form is used; Profile Solution techniques employ low-lint disposable cloths which trap and remove loose dust without building up a static charge during use.

Tacky / Sticky Mats

Sticky Mats are adhesive-coated contamination control mats capture particulates from foot traffic and equipment wheels, preventing debris from hitchhiking into the clean room or controlled environment. Adhesive is non-transferable and contains a non-leeching, nontoxic antimicrobial agent that provides long-lasting protection against growth of mold, mildew, fungi, and algae.

- Dimension – 24″ x 36″

- 30 layers / Mat with numbered corner taps for easy monitoring of usage.

- Adhesive is strong, water soluble, anti-microbial and does not contain benzoic acid.

- Removes air-borne contaminants up to 95% of particles at the 0.3 micron range.

- Capture dirt and dust from foot traffic and equipment before they enter a controlled environment with these cleanroom mats

Related Products

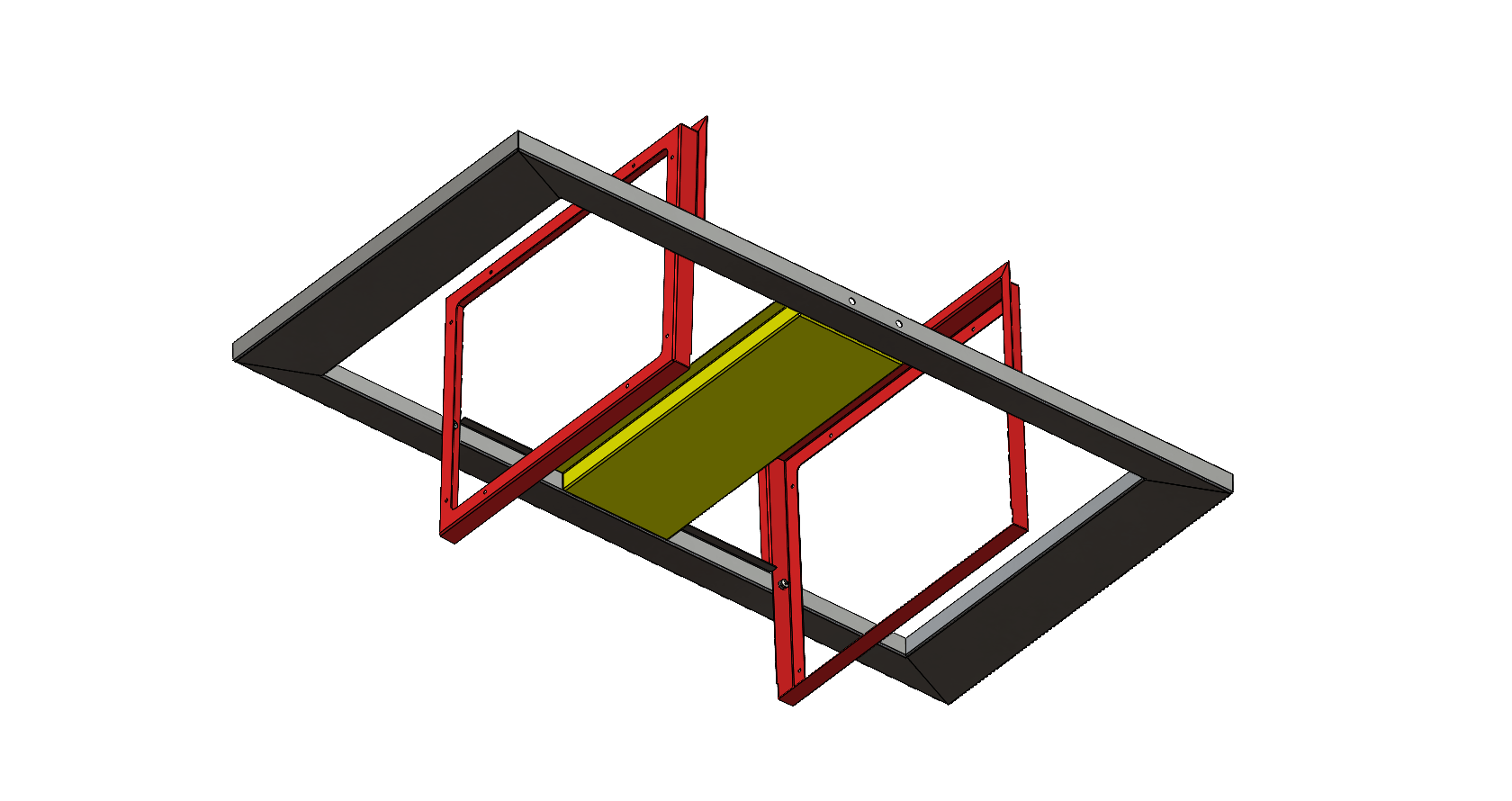

Data Center Aisle Containment

Air Flow Management System